QM.AID

“Quality Is Our Vision”

Quality Management Aid (QM.AID)

Addressing Quality Management Challenges in Multi-Tier Supply Chains

In complex, multi-tier supply chain environments, achieving consistent quality management can be challenging due to:

- Limited real-time visibility into product quality caused by paper-based processes, ineffective communication, and unclear roles.

- Variability in human labor quality affecting consistency.

- High labor costs from redundant quality checks.

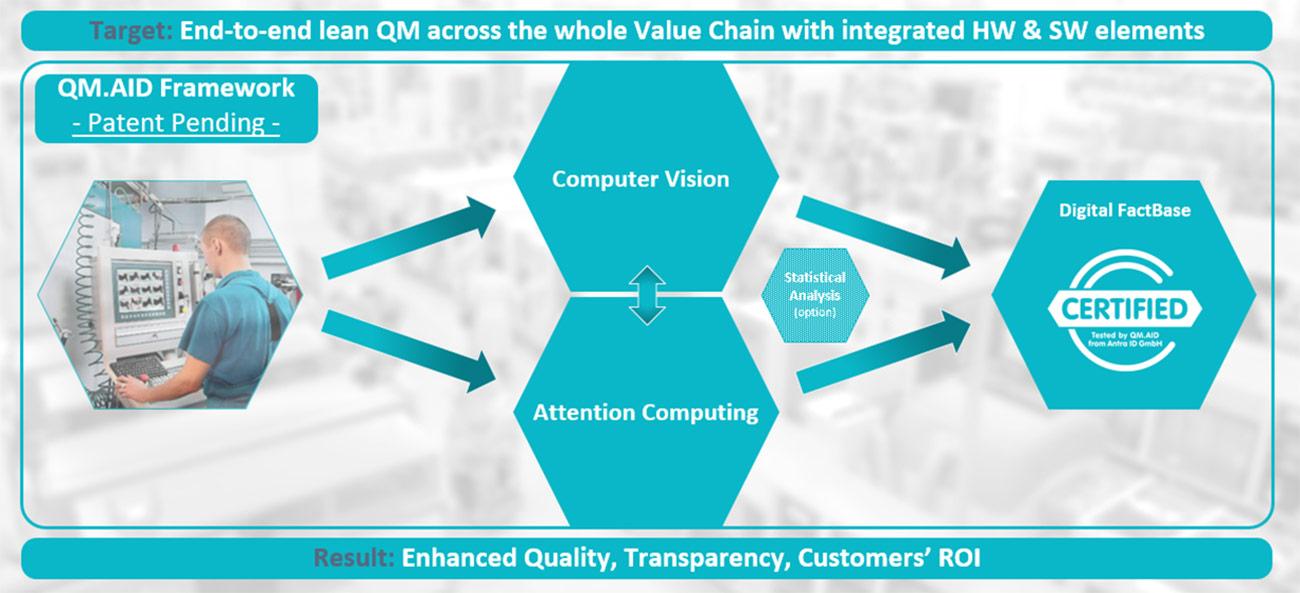

QM.AID by Antra ID GmbH with its patent pending procedure addresses these challenges, offering solutions to enhance efficiency in human-based quality control procedures. By aligning advanced technologies directly with your shop-floor needs, QM.AID brings practical, state-of-the-art solutions to enhance your quality control efficiency and competitive edge.

Click on the image to enlarge

The solution

QM.AID is a unique digital platform: we take care both of the product and the human inspection quality as well.

QM.AID is an advanced software tool designed to automate, digitalize, and enhance quality control processes. Leveraging powerful image analysis capabilities, QM.AID integrates seamlessly with various imaging sources, including microscope, X-ray, infrared, and other cameras.

Click on the image to enlarge

Key Features:

- Real-Time Support for Operators:

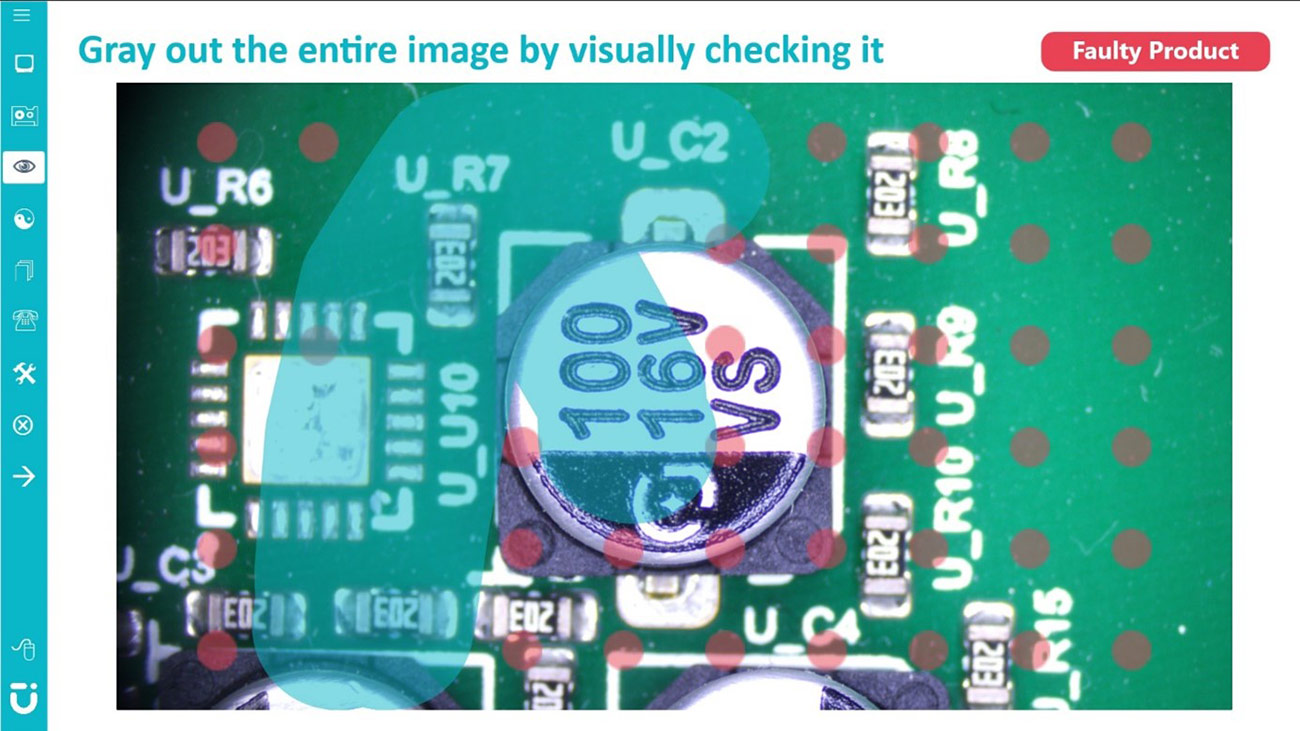

- Computer Vision for Quality Decisions: Using ASUS IoT AISVision, our computer vision technology identifies anomalies and makes quality recommendations based on sophisticated image processing algorithms.

Click on the image to enlarge

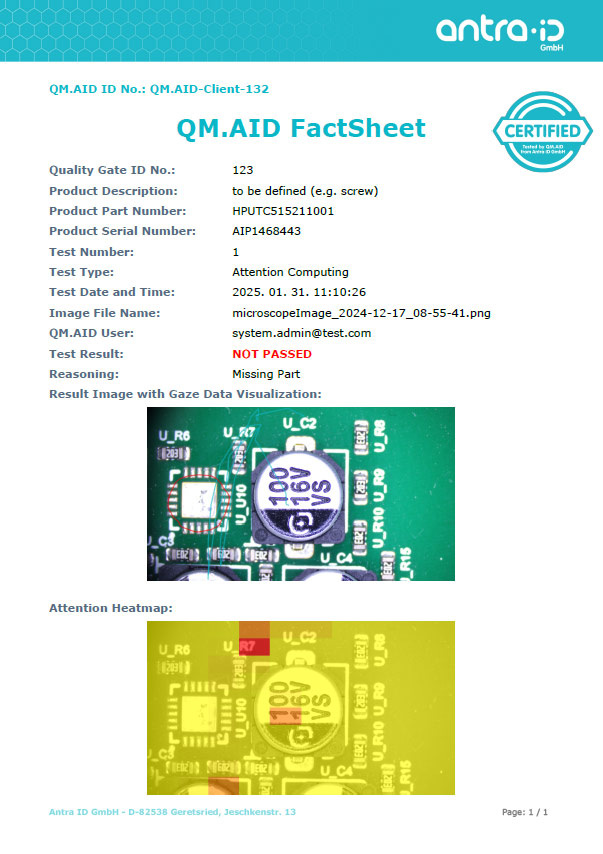

- Real-Time Attention Computing: In partnership with Tobii, QM.AID delivers gaze tracking, eye position, pupil diameter, user presence, and head pose data, ensuring consistent human observation for complete product assessments. Of course, ensuring that all data handling aligns with GDPR regulations.

Click on the image to enlarge

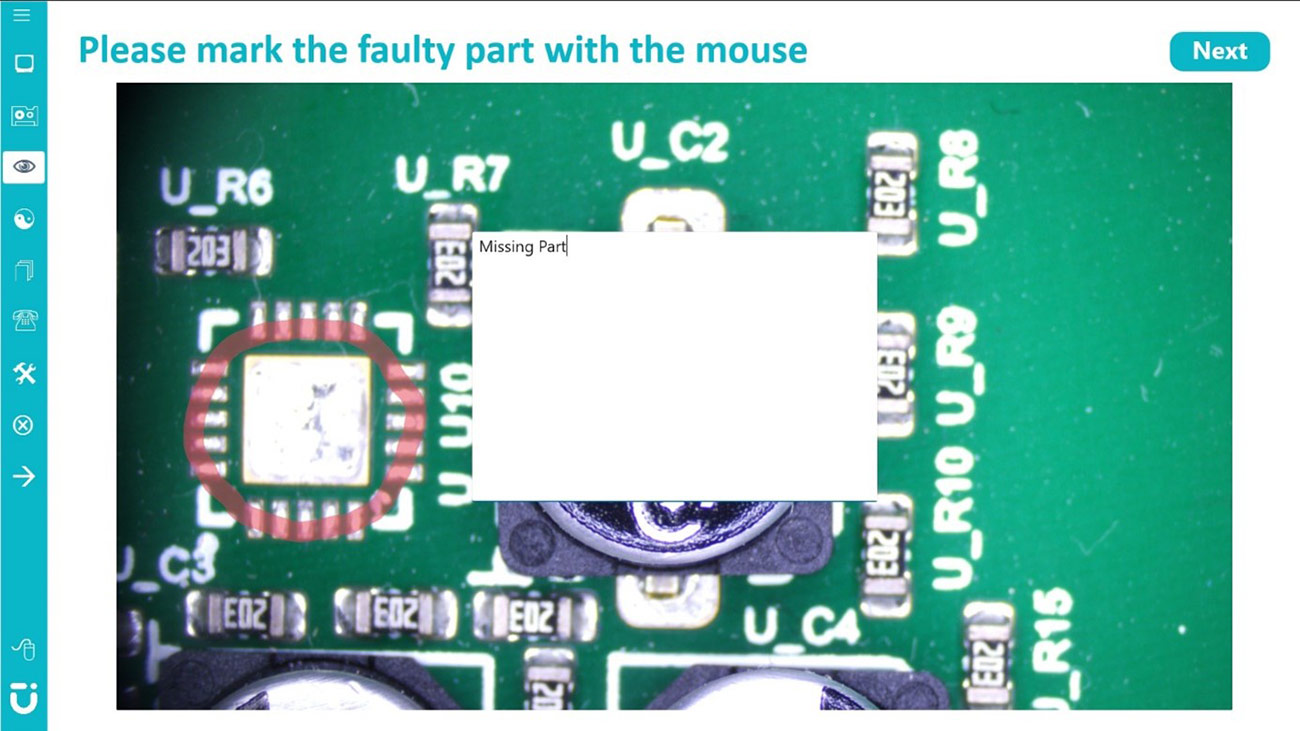

- Real-Time Faulty Product Escalation: QM.AID allows the operators to mark the faulty part and add comment to that.

Click on the image to enlarge

- Enhanced Process Development:

- Digital gaze data and analytics provide a basis for continuous quality process improvements.

The above features can come together with special additional services like synthetic image generation, model training or statistical analysis of behavior.

QM.AID is a modular, scalable solution designed to bring practical, state-of-the-art quality control to your production environment.

Enabling Efficient Communication Across Multi-Station or Multi-Tier Supply Chains

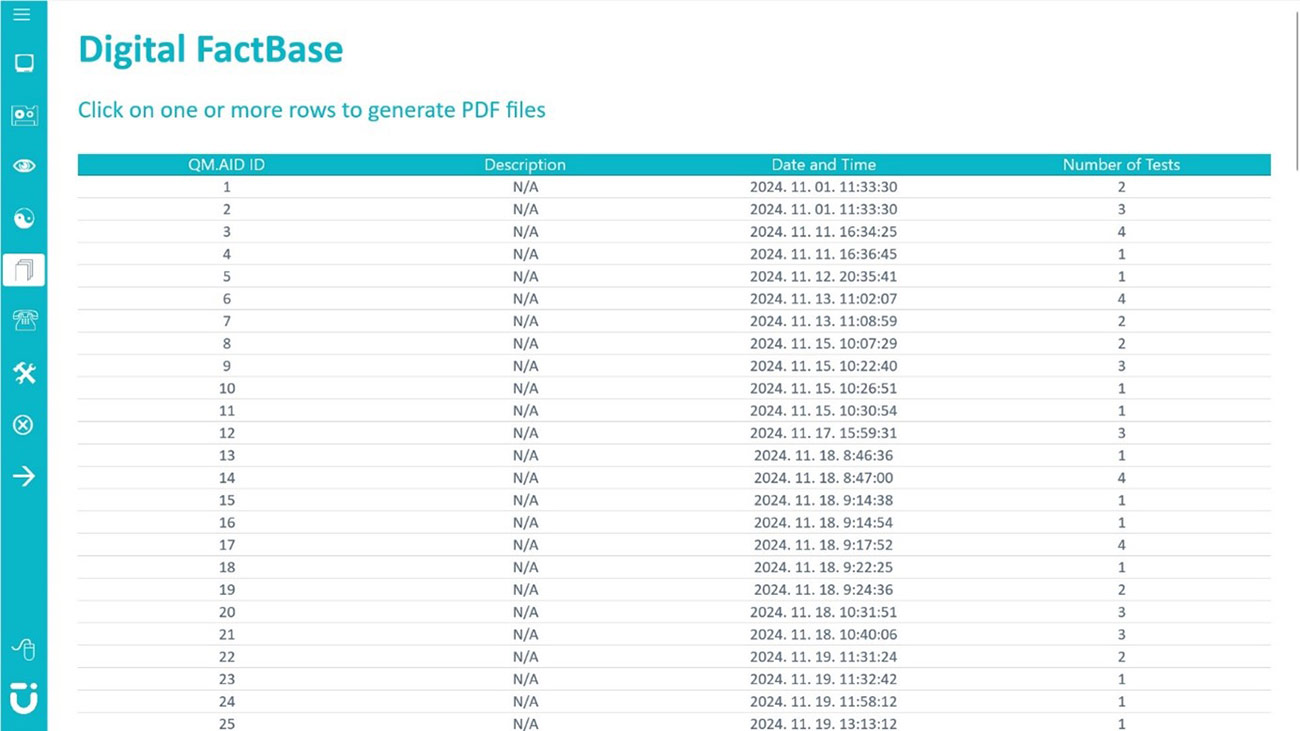

Our QM.AID Digital FactBase collects real time, digitalized quality related data and quality certificates from the implemented technologies at the shop floor, making them accessible to all relevant stakeholders. This ensures seamless tracking of your product throughout the entire value chain. You can implement it only within your internal production or with a similar logic you can include your suppliers as well.

Click on the image to enlarge

The Benefits

By applying QM.AID we provide a virtual quality data sheet called FactSheet with the related quality certificate (either virtual or physical), which holds all the valuable information about the examination of the product and its result. The related product FactSheets can be assembled virtually. All the data is then collected and shared in the Digital FactBase among the relevant supply chain stakeholders, enabling a traceable, digitalized and transparent process.

Click on the image to enlarge

These technologies can be used independently or logically connected to each other. With QM.AID besides getting special features and CX (Customer Experience) you can achieve a reasonable ROI (Return on Investment):

- Efficient Quality Control process

- End-to-end Quality Control tracking process protocol

- Possible introduction of an automated Quality Control

Improved Efficiency and Quality Control = Lower Costs and Waste = ROI

Step into the digitalised future with QM.AID, where processes, quality and returns are taken to the next level!

Contact Us